254SMO Stainless Steel Plate

254 SMO is a stainless steel originally used in seawater and other aggressive chloride environments. This grade includes a very high-end austenitic stainless steel; consisting primarily of 17.5 to 18.5 percent nickel, 19.5 and 20.5 percent chromium, 6 to 6.5 percent molybdenum, and. 18 to. 22 percent nitrogen. In this "super austenitic" chemistry, these specific levels of Cr, Ni, Mo and N give the 31254 impact toughness to resist cracking, pitting and crevice corrosion, and almost twice the strength of 300 series stainless steel.

Category:

Stainless Steel Plate

Keywords:

254SMO Stainless Steel Plate

DETAILS DESCRIPTION

254SMO Stainless Steel Plate Description

254 SMO is a stainless steel originally used in seawater and other aggressive chloride environments. This grade includes a very high-end austenitic stainless steel; consisting primarily of 17.5 to 18.5 percent nickel, 19.5 and 20.5 percent chromium, 6 to 6.5 percent molybdenum, and. 18 to. 22 percent nitrogen. In this "super austenitic" chemistry, these specific levels of Cr, Ni, Mo and N give the 31254 impact toughness to resist cracking, pitting and crevice corrosion, and almost twice the strength of 300 series stainless steel.

Product Parameters

|

Product Name |

254SMO Stainless Steel Plate |

|

Type |

Plate |

|

Thickness |

0.3mm-200mm |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

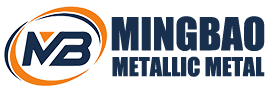

Surface |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Scope of Application |

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

|

Certificate |

ISO, SGS, BV, etc. |

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Edge Processing |

Edging, Trimming |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

|

≤ 0.02 |

≤ 0.8 |

≤1.0 |

19.5~20.5 |

17.5~18.5 |

6.0~6.5 |

≤ 0.01 |

≤ 0.03 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥680 |

≥300 |

≥45 |

≤ 180HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.0 |

195 |

16.0 |

14.0 |

85 |

Surface Selection

PACKING AND DELIVERY

Packing and delivery

Our company mainly produces stainless steel, galvanized steel, carbon steel, etc., which are suitable for engineering, coal mining, textile, electricity, boiler, machinery and other fields. We adhere to the management policy of "quality first, service first, continuous improvement and innovation, customer satisfaction" and take "zero defects, zero complaints" as the quality goal.

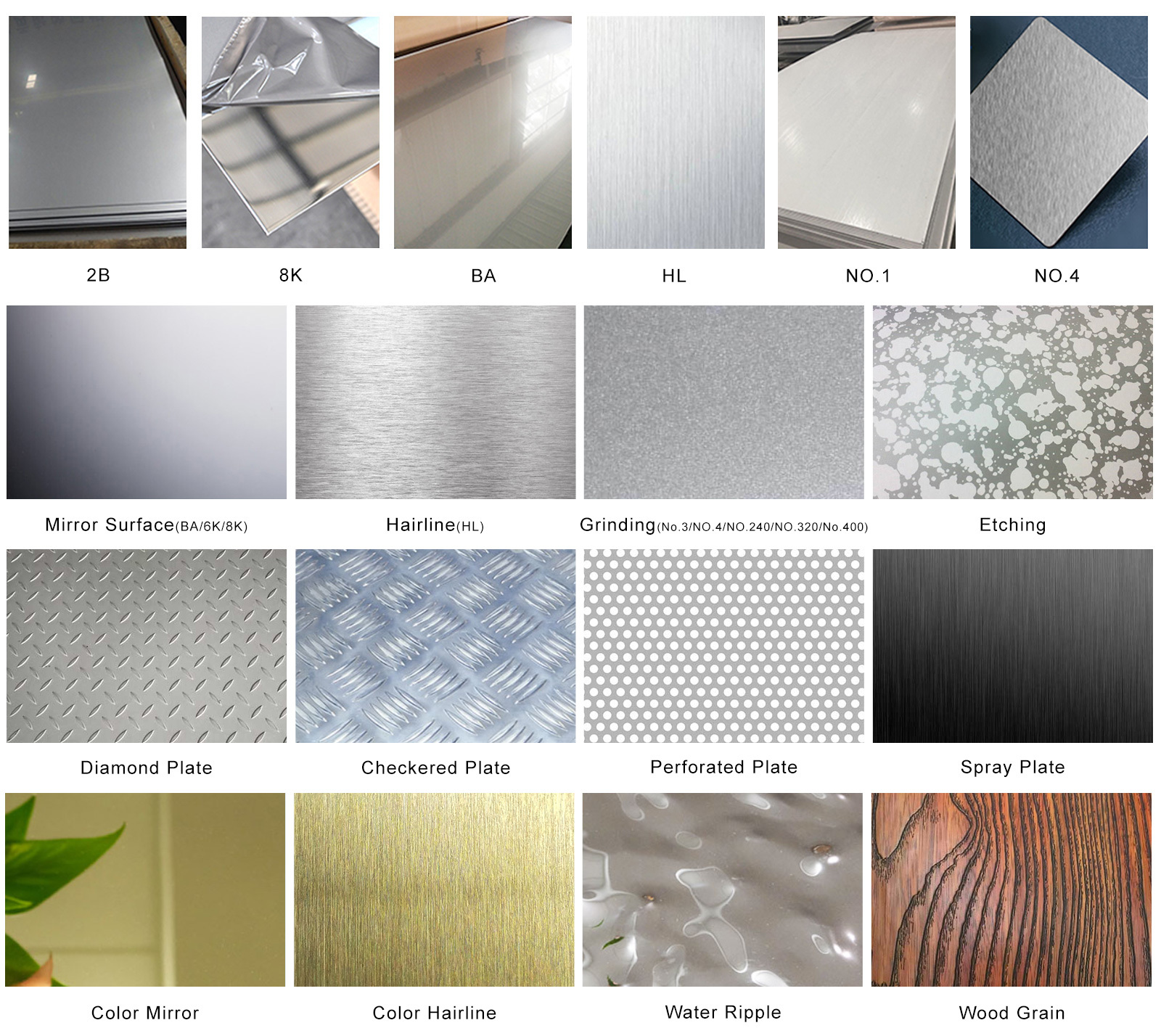

FACTORY APPEARANCE

Shandong Mingbao Metal Materials Co., Ltd. was established in 2015 and is located in Jinan City, Shandong Province. It has a plant area of 20,000 square meters. The annual output is 200,000 tons. We have passed the ISO9001 quality system certification and the EU CE certification. We focus on the production and sales of steel in Shandong area, so we have a high supply capacity.

APPLICATION AREAS

It is applicable to engineering, coal mining, textile, electricity, boiler, machinery and other fields. We adhere to the management policy of "quality first, service first, continuous improvement and innovation, customer satisfaction" and take "zero defects, zero complaints" as the quality goal.

CUSTOMER VISIT

FAQ

Do you provide samples Is it free or extra?

What certifications do your products have?

What is the delivery time?

What is your MOQ?

Once the products received by customer were found not comply with the products or contract demands, what will you do?

What kind of payment terms would you accept?

Related Products